|

Victor

Equipment Resources visits client at Ho Chi Minh City, Vietnam.

|

Victor Equipment Resources’ Sales Manager, Samson, had a Product Installation, Set-up & Training visit for the client’s staff at their R&D lab at Vietnam.

Samson helped to install and set-up the DJH Crater DFT (Dry Film Thickness) Measurement System; then provide hands-on training and basic maintenance training for the R&D staff.

The *client’s company focuses on providing services on paint & coating, internationally.

Notice*: Our client did not want their company’s name to be revealed.

Their services include:

- Coating high-performance liquid paints applied to metallic substrates*.

- Supplying high-durability coatings for agricultural, construction and earthmoving (ACE) equipment. Including, coating finishes for trucks, Automotive Plastics Exteriors (APE) and the railway segment.

- Providing coating-finishes for the consumer electronics and lifestyle appliances.

*Substrate: a material that provides the surface on which something will eventually be placed or decorated on it.

The product that was being briefed by Samson was

the DJH

Crater DFT Measurement System, a product supplied by DJH Designs

Inc., a company that specialises in designing and

manufacturing high-precision fixtures and equipment.

|

An

image of a Typical Set-up for a Crater

Film Build Measurement System. (From Left to Right) A printer (optional),

with the product’s DJH view system

software installed into a computer,

a Microscope equipped with a high

resolution camera and a Borer

Machine.

|

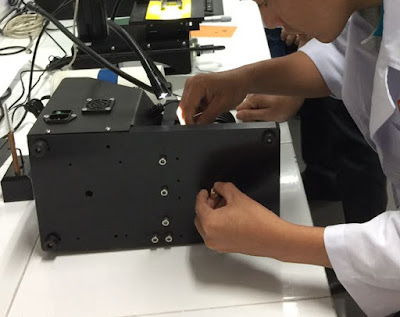

| Product placement for DJH Crater DFT Measurement System at the client’s R&D lab at Vietnam. |

Our client, needed this product to help them

measure & analyse their coating products to make sure that they are not:

- Under-coated - Having a lack of quality due to less resources used to apply the product onto a material.

- Over-coated - providing the same quality at the expense of wasting additional resources that was needed to apply the product onto a material.

Instead of relying on a conventional coating thickness measurement and analytical instruments like:

- Any typical (Digital, Magnetic & Ultrasonic) coating thickness gauge - which analyses a coating thickness, manually and one-measurement-per-usage.

- Coulometric Coating Thickness Gauge - Galvano Test, which includes the use of chemicals & metallurgic techniques to measure a coating thickness of a product or material.

Our client picked the DJH Crater DFT Measurement System because it has DJH View software that provides an all-in-one measurement system (with a full array of imaging, archival, and reporting tools) that allows multiple calibration support.

In fact, up to 9 different calibrations can be stored and recorded for different demand of applications.

How the measurement system works

The sample piece is then placed under the microscope and the crater is viewed on the high-resolution coloured video monitor and the different film layers like the metal surface, undercoat, and top layer of paint can be easily viewed and measured by the DJH View. The data collected will be analysed and shown in the DJH View software in the computer.

|

| Client’s R&D staff, viewing the end-result of their work with the DJH View software to analyse the measurement of the sample material. |

|

| One of our client’s R&D staff, learning on how to replace the drill bit in the Borer Machine; the drill bit is the only part will go through the wear-and-tear process. |

For more information onto the product, visit

(under Film Thickness Measurement System & DJH View): http://www.victormaterial.com/Coating-Test-Equipment/

===========================================================================================

Enjoyed the read? If you want to keep up with our news, stories, updates & progress:

=========================================================

Victor Equipments Resources Sdn Bhd (1021443-H) specialises in sample preparation and

providing various material testing equipment for industries that work with:

metals, plastics, rubber & elastics, leather, textile, paper and

electronics. To measure, evaluated and investigate a material’s characteristics

such as: tensile strength, compression strength, wear-resistance, fatigue test,

etc. (http://www.victormaterial.com/)

No comments:

Post a Comment